Posted by Ms.Yan

in Industry News

Technical Engineer

Updated 2025-12-17

101 Introduction to PVC Stabilizer in Power Cables

Read:355

Source:

Industry Background

Electric wires and cables are electrical wire products used for transmitting power, conveying information, and achieving electromagnetic energy conversion. They are essential items in people's daily lives.

As important materials for transmitting power and information, electric wires and cables require good insulation, flame retardancy, and physical properties. Commonly used wires and cables are mostly made of PVC or rubber, which offer excellent performance at an affordable price.

Electric wires and cables mainly consist of conductors, insulation layers, shielding, and sheathing layers. The conductors require excellent transmission capabilities, the insulation layer requires high resistance and chemical resistance, and the sheathing layer requires strong flame retardancy.

What are PVC Wires and Cables?

This report focuses on polyvinyl chloride wire and cable.

PVC wires and cables belong to soft polyvinyl chloride(flexible)products and are mainly used in PVC wire insulation and PVC jacket cable(sheathing layers).

Electrical wires and power cables are industrial products that are ubiquitous in daily life. Due to the special functions of them, they often encounter various malfunctions during long-term use. With increasing service life, PVC wires and cables may experience fires due to factors such as line aging, overload, and short circuits. PVC stabilizers can effectively slow down the problem of electrical wire aging, improve the service life and prevent cable failures.

The Role of PVC Stabilizers in PVC Cables

Stabilizers can be mainly divided into calcium zinc stabilizer and lead salt stabilizer. With increasing environmental protection requirements, Ca Zn stabilizers are currently dominating the PVC stabilizer market, not merely in wire and cable application.

Plastic stabilizers can improve various properties of PVC coated wire and cables, such as initial color, extrusion speed, surface gloss, electrical resistance, physical properties after thermal aging, and long-term temperature resistance. Long-term temperature resistance is particularly important for PVC cable and wire covers. Excellent calcium-zinc stabilizers can effectively inhibit the release of HCl from PVC wires and cables, maintain excellent stability under high-temperature conditions, significantly increase the Congo red time of wires and cables, and improve safety performance.

Aimsea AIMSTA-6703B is an environmentally friendly and non-toxic calcium zinc stabilizers for PVC with excellent thermal stability.

Experimental Verification of PVC Heat Stabilizer

This report verifies the thermal stability performance of AIMSTA-6703B through three aspects: static aging experiment, Congo red test, and seven-day heat aging experiment.

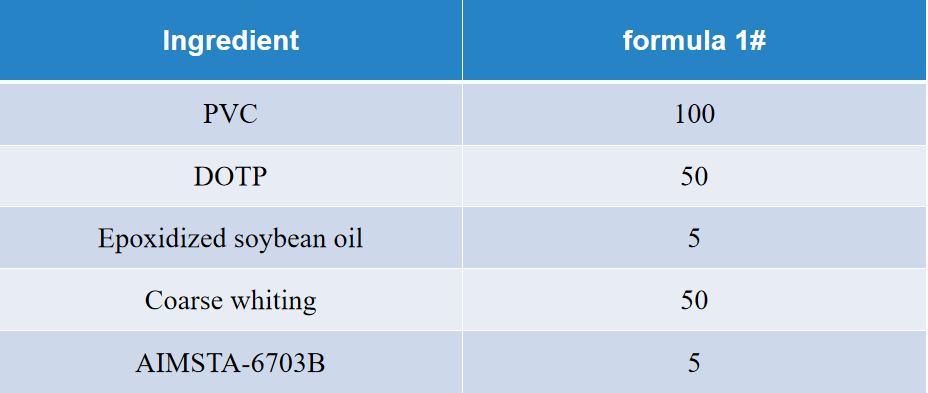

The experimental formula is shown in the table below:

Heat Stability Test of PVC

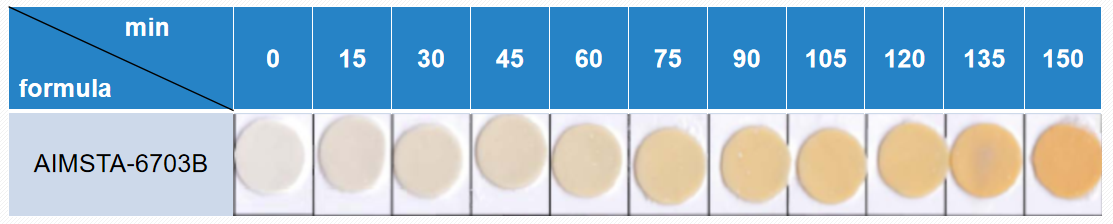

Static Aging Experiment

Mixing was performed on an open-type mixing mill at a temperature of 190±2℃ for 3 minutes to prepare samples. Then, 10 circular samples with a diameter of 16 mm were prepared from the sample sheets, placed on aluminum foil, and put into a 401A aging test chamber at a temperature of 190±1℃. One sample was taken out every 15 minutes.

Congo Red Test

The sample was cut into pieces and placed in a test tube to the lower marked level. A 5 mm wide pH red test paper ring was placed in the test tube so that the lower edge of the test paper ring was at the upper mark. Then the test tube was sealed with a cork or rubber stopper and placed in a beaker containing glycerin at a temperature of (200±2)℃. Timing was started, accurate to the minute. The time elapsed until the lower edge of the pH test paper began to turn to pH=3 was considered the thermal stability time. The test result is the arithmetic mean of two samples.

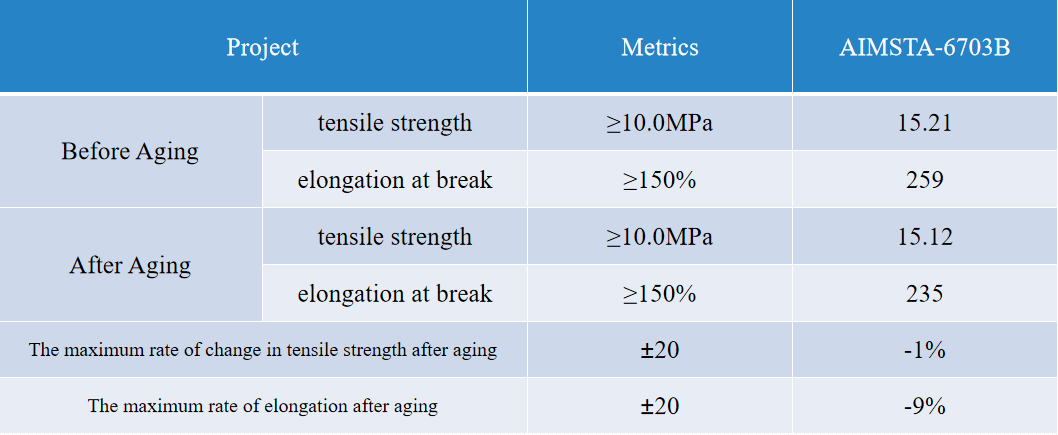

Physical Performance Test After Heat Aging

The mixed sheets obtained from the static aging experiment were pressed into uniform thin sheets with a thickness of approximately 1.0 mm using a flat vulcanizing machine. Dumbbell-shaped samples were prepared using a slicing machine. A tensile testing machine was used to test the tensile strength and elongation at break. Then, samples were prepared again according to the above steps and placed in a 100℃ oven with an air exchange rate of 13 times. After 168 hours, the samples were taken out, and the tensile strength and elongation at break were tested again using a tensile testing machine. The maximum change rate of tensile strength after aging and the maximum change rate of elongation after aging were calculated. The color changes of the samples prepared according to the above formula after 150 minutes of static aging experiment are shown in the table below:

Conclusion

From the results of the static aging experiment and the Congo red test, it can be seen that AIMSTA-6703B has excellent static aging performance and long-term temperature resistance, a wide range of applications, and is suitable for the production of various types of wires and cables. It can also extend their service life , slow down line aging, and reduce safety hazards. It is a cost-effective, highly applicable, non-toxic, and sustainable calcium compound stabilizer for pvc cable.